Powder Flowability Testing and Material Properties Test Lab

The Power Flowability Testing and Material Properties Test Lab provides powder and bulk solid material testing services; flow modeling, including CFP, FEM and DEM; and has a variety of bulk material equipment for your company's additional needs.

Powder and Bulk Solid Material Testing Services

Why is it important to understand the properties of your powder or other bulk solid material? In many cases, material characterization and understanding material properties are the first steps in solving issues and achieving the best design.

Examples of challenges and recommended material tests include:

Designing dry bulk storage and transport

Which silo design is best? Will the material cake in transit on a truck or rail car and will it come out of the transport vessel? Will flow properties change if this powder is stored for a long period in a bag or supersack? Will the bulk density change?

Designing proper flow through chutes and hoppers

Is funnel flow acceptable, or is mass flow needed for this bulk solid material? How do I achieve mass flow? Which flow aid devices will work best for this material? What is the minimum outlet dimension for my hopper? What angle is required for my gravity flow chute? The recommended tests are:

- Wall friction

- Flow factors, flow function

- Flow function with time consolidation

- Angle of friction, fall, difference, spatula

- Angle of repose

- Cohesive strength

- Fluidizability / Dispersibility

- Particle size distribution

- Particle shape

- Bulk density, loose and packed; compressibility

- Abrasiveness

- Moisture content

Designing particulate air filtration and dust collection systems

Will a cyclone be adequate, or do I need a filter with filter bags or maybe cartridges? What filtration efficiency should be expected with my material in a cyclone or baghouse? What type of filter media should be used in the filter bags or cartridges for my particular powder or bulk solid? What air velocity should be used in the ducting going to my dust collector? How much static pressure does my fan need?

- Particle size distribution

- Particle shape

- True particle density

- Terminal velocity

- Can velocity

Designing conveying systems

Which type of conveying system is best for my bulk solid material? Should I use mechanical conveying? If so, should it be tubular or belt or screws? Should my pneumatic conveying system use vacuum or pressure? Dense phase or dilute phase pneumatic conveying? How can I reduce particle degradation? How do I reduce energy consumption when conveying? How do I prevent build up or cross contamination?

- Particle size distribution

- Particle shape

- Bulk density, loose and packed or tapped

- Abrasiveness

- Cohesiveness

- True particle density

- Terminal velocity

- Can velocity

- Saltation velocity

Selecting process equipment, such as mixing, particle size reduction, agglomeration, fluidization, feeding, weighing and drying

Test examples include measuring the effects of Flow additives, changing moisture content, environmental differences in temperature and humidity, wet granulation end point, attrition, particle surface area and texture, electrostatic and explosibility characteristics, segregation potential, caking tendency, compressibility, permeability, morphology, moisture sorption isotherms.

Changing your process / Changing the formulation of your product

If you change something, how will it affect your production process? How can you test scale up from lab scale to pilot scale to production without shutting down your systems to try it? If you change formulation or try a different ingredient, will it affect the processing? Will it effect flowability, abrasive wear or efficiency of the process?

Troubleshooting and solving issues

How do you solve these problems with your powder and bulk solid equipment? Process challenges include unreliable flow, not making rate, wear and abrasion, filter elements requiring frequent change.

Do I need a small sample test of material properties or is a full-scale test of the system required?

Material properties testing with a small sample of product is normally the first step. It is less expensive, requires less material and will answer many questions.

Sometimes, a full-scale test will be required, especially if system-specific details are required such as: how much particle degradation or build up will occur? Or, which elbow is best to prevent particle attrition or build up? In these cases, it is important to set up the parameters of the laboratory full-scale system as closely as possible to the plant’s production system. Furthermore, the small bench-scale testing is never unneeded — in fact, results of the materials property testing will be used to design and set up the full-scale system.

Flow Modeling: CFD, FEM and DEM

Kansas State University employs a number of digital modeling methods.

Material properties are measured, then used in the model to examine issues such as:

- Powder and bulk solid flow patterns

- Gravity flow rates of bulk solids

- Velocity profiles of the particles; fast and slow zones

- Particle segregation tendency and patterns during filling and discharging

- Stress distribution within materials and equipment; force and impact within various equipment designs

- Wear patterns

- Sizing and performance of various conveying methods

Bulk Material Testing Equipment

Powder Flow Tester

The Brookfield Powder Flow Tester (PFT) is an automated shear cell tester used for analyzing powder flow behavior in storage, handling and conveying of bulk solids. Powder testers assist in research, new formulation, process development, equipment design and troubleshooting of material flow problems.

The Brookfield Powder Flow Tester (PFT) is an automated shear cell tester used for analyzing powder flow behavior in storage, handling and conveying of bulk solids. Powder testers assist in research, new formulation, process development, equipment design and troubleshooting of material flow problems.

Properties Measured

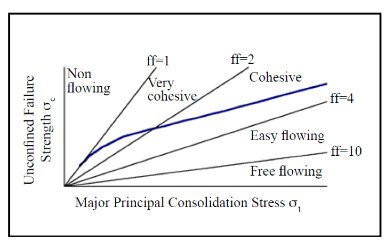

Flow Function — a measure of the internal resistance to flow of a powder causing blockage (usually an arch or a rat-hole) in a hopper or feeder

Flow Function — a measure of the internal resistance to flow of a powder causing blockage (usually an arch or a rat-hole) in a hopper or feeder- Time Consolidation Flow Function — similar to the Flow Function, but with an understanding of how storing the powder for a period of time can lead to poor powder flow when restarting after a shut-down.

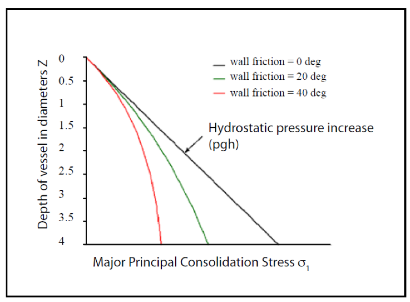

- Wall Friction — the friction developed between the powder and a constraining surface of bins, hoppers, and chutes.

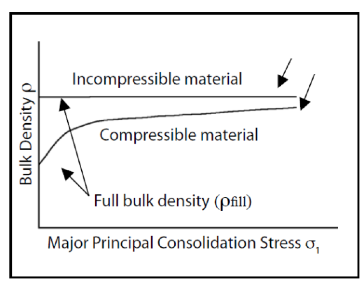

- Bulk Density and Compressibility — affects the ability of powder flowability.

Choice of Test Options

Flow Function (relation between consolidation stress and powder strength)

Flow Function (relation between consolidation stress and powder strength)- Angle of internal friction

- Angle of wall friction

- Cohesive strength

- Bulk density

- Time Consolidation

Use of Measured Properties

Flow Index

Flow Index- Arching Dimension

- Rat-hole Diameter

- Hopper Half Angle

- Gravity Chute (Wall Friction) Angle

- Bulk Density Curve

Powder Tester

The Hosokawa PT-X Powder Tester is a comprehensive powder characteristics evaluation device (a single measuring instrument) that can quantitatively evaluate the "flowability" and "floodability" of powders that Mr. R.L.Carr advocated.

The Hosokawa PT-X Powder Tester is a comprehensive powder characteristics evaluation device (a single measuring instrument) that can quantitatively evaluate the "flowability" and "floodability" of powders that Mr. R.L.Carr advocated.

Properties Measured

- Flowability — the movement of a powder from a stationary to a moving state.

- Angle of Repose — the indication of the potential flowabilities of a powder sample.

- Angle of Fall — the angle between the slope of the collapsed pile and the horizontal plane.

- Angle of Difference — the difference between the Angle of Repose and the Angle of Fall.

- Angle of Spatula — determined property that gives a relative angle to of internal friction of a dry powder sample.

- Cohesion — the natural attraction of dry powder particles to each other. It is an indication of the "flowability" of the powder sample.

- Compressibility — determined by the relative measurement of loose and packed bulk density

- Dispersibility — the scattering/dusting and/or flushing of a dry powder sample.

- Uniformity — defined as the ratio of particles of a given sample at the value points of d60 divided by the d10

Choice of Test Options

- Angle of Repose

- Angle of Fall

- Angle of Difference

- Angle of Spatula

- Cohesion

- Compressibility

- Dispersibility

- Aerated Density

- Uniformity

- Packed Density

Use of Measured Properties

Measurement results are to quantitatively evaluate the "flowability" and "floodability" of powders.

True Particle Density

The QuantaChrome UltraPyc 1200e Automatic Gas Pycnometer is used for the measurement of true density and volume of solids. Air is replaced with an inert gas, and the differences are measured.

The QuantaChrome UltraPyc 1200e Automatic Gas Pycnometer is used for the measurement of true density and volume of solids. Air is replaced with an inert gas, and the differences are measured.

Properties Measured

- True particle density

- True particle volume

- Bulk density, defined as the ratio of the mass of a bulk solid to its volume

Use of Measured Properties

- Determines the space occupied by a given amount of material

- Characterize a material in order to design equipment and assess its behavior during process operations e.g., blending, compaction, dense phase conveying, and particulate air filtration

- Identify material changes, e.g., particle size or shape in various steps of the process

Particle Size Distribution

The Hosokawa Mikro Air Jet Sieve® is an accurate and reliable particle size analyzer designed to determine the particle size distribution of dry powders ranging from 20 to 4,750 micron.

The Hosokawa Mikro Air Jet Sieve® is an accurate and reliable particle size analyzer designed to determine the particle size distribution of dry powders ranging from 20 to 4,750 micron.

Properties Measured

- Determines particle size for dry powders from 20 µm to 4,750 µm

Features

- Accurate and reliable particle size analysis for a wide variety of particle sizes

- Suitable for Chemicals, Minerals, Pharmaceuticals, Food, Plastics and Cosmetic materials

- Calculates particle size points at 0.01 to 99.99% using the Rosin-Rammler Law

- Pneumatic sieving deagglomerates the sample while continuously cleaning test sieve

Particle Size Distribution

The WS Tyler Ro-Tap E 8" Sieve Shaker is designed for analyzing particles in the size range of No.10 (2mm) to No.635 (20 micron). The Ro-TAP Shaker allows analysts to obtain particle size distributions of various materials in a standardized way by delivering consistent vertical and horizontal force on a sieve stack.

The WS Tyler Ro-Tap E 8" Sieve Shaker is designed for analyzing particles in the size range of No.10 (2mm) to No.635 (20 micron). The Ro-TAP Shaker allows analysts to obtain particle size distributions of various materials in a standardized way by delivering consistent vertical and horizontal force on a sieve stack.

A sieve analysis (or gradation test) is a practice or procedure used (commonly used in civil, chemical or mechanical engineering) to assess the particle size distribution (also called gradation) of a granular material by allowing the material to pass through a series of sieves of progressively smaller mesh size and weighing the amount of material that is stopped by each sieve as a fraction of the whole mass.

Properties Measured

- This method is intended for estimation of the total particle size distribution of a powder or other bulk solid material

Use of Measured Properties

- Determines the space occupied by a given amount of material

- Characterize a material in order to assess its behavior during process operations e.g., blending, compaction, etc.

- Identify material changes, e.g., particle size or shape

Abrasive Wear Test

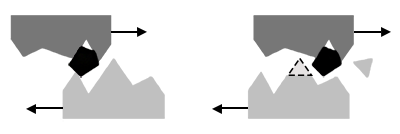

The KSU-BSTC Abrasive Wear Tester is based on ASTM611, modified specifically for evaluating the abrasive wear upon equipment used to handle dry bulk materials. In the standard configuration, a test sample coupon (such as metal, coated metal or plastic) is placed in the test chamber. Then the powder or other bulk solid material continually acts against the coupon, and the wear upon the coupon is measured. To make the test valid, fresh bulk solid material is continually fed into the abrasion point. The speed and force of the abrasion can be varied.

The KSU-BSTC Abrasive Wear Tester is based on ASTM611, modified specifically for evaluating the abrasive wear upon equipment used to handle dry bulk materials. In the standard configuration, a test sample coupon (such as metal, coated metal or plastic) is placed in the test chamber. Then the powder or other bulk solid material continually acts against the coupon, and the wear upon the coupon is measured. To make the test valid, fresh bulk solid material is continually fed into the abrasion point. The speed and force of the abrasion can be varied.

Two different wear testing configurations are available. The first is a standard Abrasive Wear Tester, recommended for typical applications such as mechanical conveyors, bins, chutes and slow speed mixers. This is a three-body abrasive wear test, with a test coupon, a bulk solid material and a device which rubs the bulk solid against the test coupon. The second configuration is a High Velocity Abrasion Tester, recommended for evaluation of wear in dilute phase pneumatic conveying, blasting and high speed mixers. It is two body abrasive wear tester in which the bulk solid impacts against the test surface at high velocity.

The KSU-BSTC Abrasive Wear tester is relevant in a variety of applications, including:

- Will the desired equipment stand up to wear from this particular bulk solid?

- How long will the equipment last with an abrasive material?

- Which type of conveyor should be used?

- Should the equipment be built from standard metal, or would an exotic metal, coating or plastic be better?

- What if the bulk solid changes?

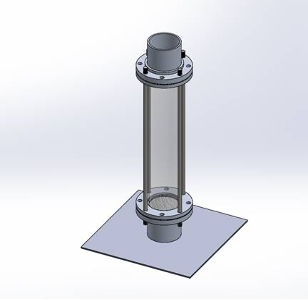

Fluidization Testing

Fluidization testing is performed by pushing a volume of air through a bed of material to determine how well the air gets entrapped between particles. A material that entraps the air will flow easily, but it also can flow too easily creating spillage and flooding of the powder. On the other hand, a material that does not fluidize well may not easily transport and can create other issues. Optimal air pressure and air flow for a bed of material can be measured and optimized. Additionally, the fluidization equipment can be utilized to measure how long a fluidized bed of material will stay aerated after the air flow is stopped.

Fluidization testing is performed by pushing a volume of air through a bed of material to determine how well the air gets entrapped between particles. A material that entraps the air will flow easily, but it also can flow too easily creating spillage and flooding of the powder. On the other hand, a material that does not fluidize well may not easily transport and can create other issues. Optimal air pressure and air flow for a bed of material can be measured and optimized. Additionally, the fluidization equipment can be utilized to measure how long a fluidized bed of material will stay aerated after the air flow is stopped.

Powder Rheometer

The Freeman FT4 Powder Rheometer is a universal powder tester. It employs a patented dynamic methodology, in which a powder's resistance to flow is measured while the powder is in motion. The FT4 also includes a shear cell for measuring bulk flow properties.

The Freeman FT4 Powder Rheometer is a universal powder tester. It employs a patented dynamic methodology, in which a powder's resistance to flow is measured while the powder is in motion. The FT4 also includes a shear cell for measuring bulk flow properties.

Properties Measured

Basic Flowability — used for measuring the effects of:

- Flow additives

- Wet granulation and point

- Moisture content

- Attrition/Segregation

- Physical properties (particle size, shape, surface texture)

- Electrostatic charging

Aeration — used for measuring:

- Cohesion

- Low stress, gravitationally induced flow

- Dosing/Mass uniformity

- Fluidization behavior

- Blending/Mixing

- Segregation potential

Consolidation

- Direct pressure

- Tapped

- Understand the effects of:

- Transport

- Storage

- Processing

- Caking

Shear Cell

- Unconfined Yield Strength (UYS)

- Flow Function

- Cohesion

- 1 ml shear cell

- Hopper design

Wall Friction

- Measure friction between powder and surface material – Hopper, IBC, Punch

- Wall friction angle, for hopper design

Compressibility — changes in density due to:

- Transportation

- Storage

- Hoppers

- Kegs

- Processing

- Direct compression

- Roller compaction

- Screw feeding

Permeability — powder behavior during:

- Aerosolization/DPI

- Hopper flow

- Compression

- Pneumatic transfer

Particle Morphology

The Morphology G3 SE system provides the ability to measure the morphological characteristics (size and shape) of particles. It is an analytical tool for differentiating and characterizing particulate samples.

The Morphology G3 SE system provides the ability to measure the morphological characteristics (size and shape) of particles. It is an analytical tool for differentiating and characterizing particulate samples.

SEM Analysis – Scanning Electron Microscope

SEM Analysis provides high magnification viewing of particles. Detailed analysis of surface structures and particle shapes can be performed. It can help determine how particulates form, agglomerate, fracture, and wear. It can explain why two material samples behave differently even when they have the same chemical properties and particle size.

Effects of Environment: Humidity and Temperature

Environmental changes can affect a material's properties. Powders and other bulk solid materials will behave differently if the temperature or humidity changes at the location where the materials are stored or processed. For example, some materials will behave differently in winter than in summer, or when used in different parts of the country.

The Bulk Solids Technology Center has two environmental chambers in which materials can be placed. Temperature and humidity can be selected, the material is allowed to reach equilibrium, then the material's properties are tested to determine the effect of the environmental change.

Moisture Sorption Isotherms

The VSA Isotherm Generator is an automatic moisture sorption isotherm generator that can generate both dynamic and equilibrium moisture sorption isotherms. This information indicates the relationship between moisture content and relative humidity. For each humidity value, the sorption isotherm indicates the corresponding water content value at a given constant temperature. Water activity increases as moisture content increases, but the relationship is not linear.

The VSA Isotherm Generator is an automatic moisture sorption isotherm generator that can generate both dynamic and equilibrium moisture sorption isotherms. This information indicates the relationship between moisture content and relative humidity. For each humidity value, the sorption isotherm indicates the corresponding water content value at a given constant temperature. Water activity increases as moisture content increases, but the relationship is not linear.

Materials for Testing

The Bulk Solids Center can receive dry bulk materials by truck, box, drums, bags and supersacks.

Contact Us